The Poulan Chainsaw Repair Manual PDF is a comprehensive guide for troubleshooting, maintaining, and repairing Poulan chainsaws. It covers various models, providing detailed instructions and torque specifications to ensure optimal performance and safety. Available as a downloadable PDF, this manual is an essential resource for both professionals and DIY enthusiasts, offering step-by-step solutions for common issues and advanced repairs.

1.1 Overview of Poulan Chainsaw Models Covered in the Manual

The manual covers various Poulan and Poulan Pro chainsaw models, including Poulan 2150, 1900, 1950, 2050, 2055, 2075, 2175, 2375, Wild Thing, 2250, 2450, 2550, 220, 221, 221LE, 260, and 260LE. Engine sizes range from 18cc to 50.2cc, ensuring comprehensive coverage for different user needs. This extensive range makes the manual a versatile resource for owners of multiple Poulan chainsaw models, providing specific repair guidance.

1.2 Importance of Using the Official Repair Manual

Using the official Poulan Chainsaw Repair Manual ensures accurate and safe repairs. It provides specific torque specifications, part numbers, and detailed assembly instructions tailored to Poulan models. Following the manual prevents damage, enhances performance, and extends the chainsaw’s lifespan. It also helps comply with manufacturer standards, reducing risks of injury or equipment failure. This makes it an indispensable resource for both professionals and DIY enthusiasts.

Safety Precautions and Guidelines

Always wear protective gear, including gloves, safety glasses, and a hard hat. Follow manual guidelines to avoid accidents. Ensure the chainsaw is off during repairs.

2.1 General Safety Warnings for Chainsaw Repair

The Poulan Chainsaw Repair Manual emphasizes critical safety measures to prevent accidents during maintenance. Always wear protective gear, including gloves, safety glasses, and a hard hat. Ensure the chainsaw is turned off and properly secured before starting repairs. Failure to follow these guidelines can result in serious injury or equipment damage. Understand all safety warnings and precautions outlined in the manual to ensure safe repair practices.

2.2 Essential Safety Gear for Repair and Maintenance

Protective gear is vital when performing chainsaw repairs. Essential items include safety glasses to shield eyes from debris, gloves for grip and hand protection, and a hard hat to prevent head injuries. Steel-toe boots and chainsaw chaps or leg protection are also recommended. Ensure all gear meets safety standards to minimize risks during maintenance and repair tasks. Always follow the manual’s guidelines for proper protective equipment usage.

Diagnostic and Troubleshooting Steps

The Poulan Chainsaw Repair Manual PDF guides users through identifying common issues like poor engine performance or chain malfunctions. Detailed diagnostic procedures help pinpoint problems efficiently, ensuring effective repairs and maintaining optimal chainsaw functionality. This section emphasizes systematic troubleshooting to address root causes and restore performance quickly.

3.1 Identifying Common Issues in Poulan Chainsaws

The Poulan Chainsaw Repair Manual PDF aids in identifying common issues like chain tension problems, engine performance issues, and starting difficulties. It addresses fuel-to-oil ratio mismatches and insufficient chain lubrication, which can cause poor cutting performance or engine damage. Early detection of these symptoms allows users to take corrective action, preventing minor issues from becoming major repairs and ensuring the chainsaw runs smoothly and efficiently over time.

3.2 Detailed Diagnostic Procedures for Engine and Chain Problems

The manual provides step-by-step diagnostic procedures for engine and chain issues, including checking chain tension, inspecting bar and sprocket wear, and testing engine components like spark plugs and fuel systems. It also outlines visual inspections and troubleshooting steps to identify root causes, ensuring precise repairs and minimizing downtime for Poulan chainsaw users.

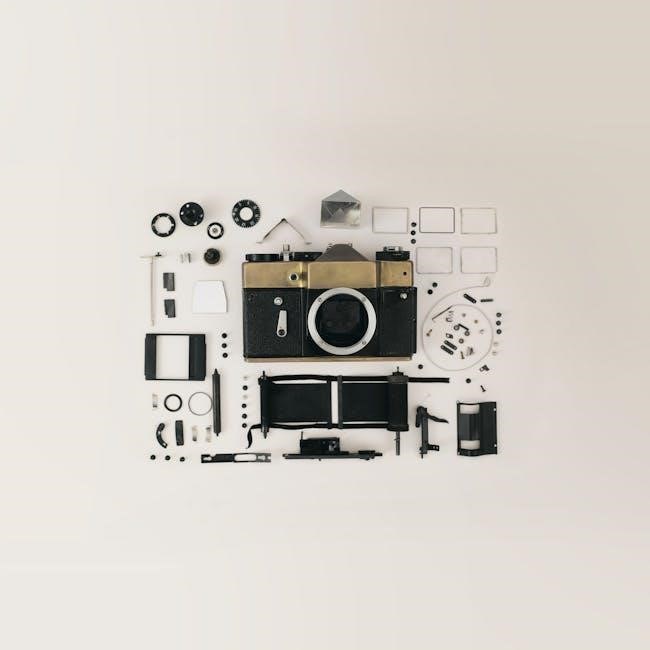

Repair and Maintenance Procedures

The manual provides detailed instructions for disassembling, inspecting, and reassembling Poulan chainsaws, including chain and bar maintenance, engine repairs, and component replacements, ensuring optimal performance and longevity.

4.1 Step-by-Step Guide to Disassembling the Chainsaw

The manual outlines a systematic approach to disassembling Poulan chainsaws, starting with removing the chain and bar, followed by the sprocket and clutch. It then guides users through accessing the engine components, including the cylinder, piston, and carburetor, while emphasizing safety and the use of specialized tools to prevent damage and ensure proper reassembly.

4.2 Reassembling and Adjusting Key Components

The manual provides step-by-step guidance for reassembling Poulan chainsaws, ensuring proper alignment and secure fastening of all parts. It emphasizes adjusting the chain tension, carburetor, and idle speed for optimal performance. Specialized tools are recommended for precise adjustments, and users are advised to reference torque specifications to avoid damage and ensure safety during the reassembly process.

Regular Maintenance Requirements

Regular maintenance ensures optimal performance and longevity of Poulan chainsaws. Tasks include checking chain tension, lubricating moving parts, and ensuring proper fuel and oil ratios are used.

5.1 Recommended Maintenance Schedule for Optimal Performance

A well-structured maintenance schedule is crucial for Poulan chainsaws. Regular tasks include daily checks of chain tension and lubrication, weekly inspections of air filters, and monthly sharpening of chains. Additionally, annual spark plug replacements and thorough cleaning of the saw ensure consistent performance. Following this schedule helps prevent breakdowns and extends the chainsaw’s service life significantly.

5.2 Fuel and Oil Specifications for Poulan Chainsaws

Poulan chainsaws require a 50:1 gasoline-to-oil mixture using Poulan 2-cycle engine oil. Avoid E15 or E85 fuels, as they can damage the engine. Use high-quality, unleaded gasoline with an octane rating of 89 or higher. Regularly check the fuel filter and ensure proper mixing to maintain optimal performance and prevent engine issues. Always refer to the manual for specific recommendations tailored to your chainsaw model.

Troubleshooting Common Chainsaw Problems

Common issues include chain tension problems, poor lubrication, and engine performance difficulties. The manual provides detailed diagnostic steps, such as checking fuel mixtures and spark plugs, to identify root causes. It also offers practical solutions, like adjusting carburetors or replacing worn parts, ensuring users can resolve issues efficiently and safely; Regular maintenance is emphasized to prevent recurring problems.

6.1 Resolving Issues with Chain Tension and Lubrication

Chain tension issues can cause poor cutting performance or premature wear. Check and adjust the tension regularly, ensuring it’s snug but not overly tight. Proper lubrication is critical; use Poulan 2-cycle engine oil to keep the bar and chain well-lubricated. Clean the bar groove and oil holes to ensure even distribution. Adjusting these elements can resolve common problems like overheating or slow cutting efficiency effectively.

6.2 Addressing Engine Performance and Starting Difficulties

Engine performance issues, such as hard starting or rough running, often stem from fuel mixture problems or air filter clogs. Check the spark plug condition and ensure proper fuel-to-oil ratio. Refer to the manual for carburetor adjustment procedures to restore optimal performance. Regularly cleaning or replacing the air filter and spark plug can prevent starting difficulties. The manual provides detailed guidance for diagnosing and resolving these common engine-related challenges effectively.

Accessing and Using the Poulan Chainsaw Repair Manual

The Poulan Chainsaw Repair Manual PDF is available for download from official Poulan websites or authorized retailers. Ensure to use your chainsaw’s model number for accurate access.

7.1 Sources for Downloading the Official Poulan Chainsaw Manual

The official Poulan Chainsaw Repair Manual PDF can be downloaded from Poulan’s website or authorized online retailers. Ensure you use your chainsaw’s specific model number for accurate access. The manual is typically available in PDF format and may require payment. It includes detailed instructions, torque specifications, and assembly guidelines. Always verify the source to ensure authenticity and avoid third-party scams.

7.2 Navigating the Manual for Specific Repair Information

The Poulan Chainsaw Repair Manual PDF is structured to help users quickly locate specific repair information. Start with the table of contents or index to identify relevant sections. Use the search function in PDF viewers to find keywords like “torque specifications” or “chain adjustment.” Detailed diagrams and step-by-step instructions guide you through complex tasks, ensuring accurate repairs. Always cross-reference your chainsaw model number for precise information;

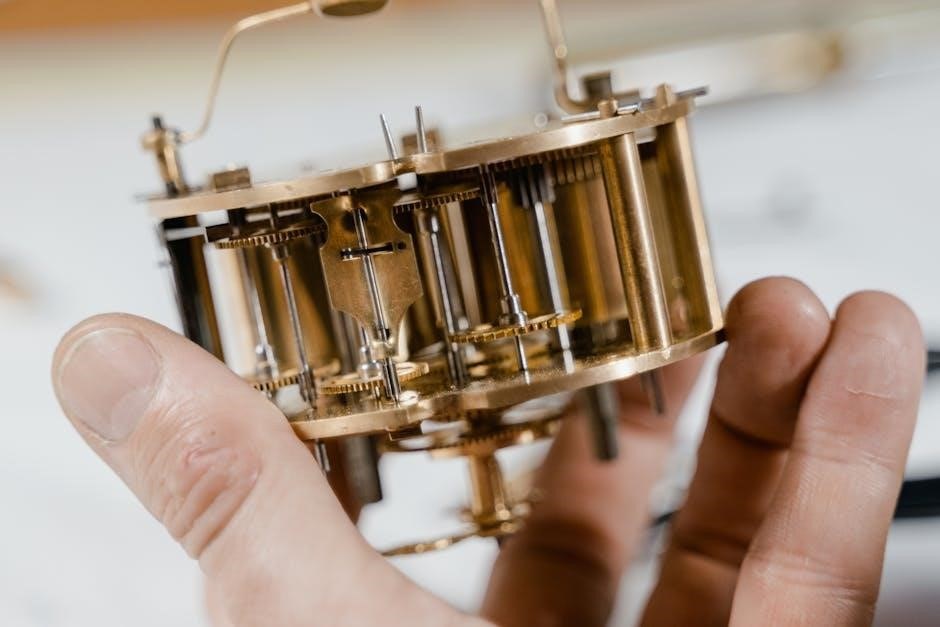

Tools and Equipment Required for Repair

Essential tools include screwdrivers, wrenches, and pliers for basic repairs. Specialized tools like piston installers and bearing pullers are needed for advanced tasks. Ensure all tools are readily available to streamline the repair process and avoid delays. Always use the correct tool for the job to prevent damage to the chainsaw components. Proper equipment is crucial for safe and effective repairs.

8.1 Essential Tools for Chainsaw Maintenance and Repair

The essential tools for maintaining and repairing Poulan chainsaws include screwdrivers, wrenches, pliers, and torque wrenches. These tools are necessary for tasks like disassembling components, adjusting chain tension, and replacing parts. Additionally, specialized tools such as piston installers and bearing pullers may be required for more complex repairs. Always refer to the manual for specific tool recommendations to ensure safe and efficient maintenance. Proper tools prevent damage and ensure optimal performance.

8.2 Specialized Tools for Advanced Repair Tasks

Advanced Poulan chainsaw repairs require specialized tools like piston installers, bearing pullers, and crankshaft tools. These tools ensure precise disassembly and reassembly of complex components. A compression tester is also essential for diagnosing engine issues. Additionally, a seal protector is necessary for installing bearings and seals without damage. These tools are often available from Poulan dealers or online retailers and are crucial for professional-level repairs. Always consult the manual for specific tool recommendations to avoid costly mistakes and ensure proper repairs.

The Poulan Chainsaw Repair Manual PDF is an invaluable resource for extending your tool’s lifespan. Regular maintenance, safe practices, and proper tool usage ensure optimal performance. Refer back to the manual for future repairs and always follow safety guidelines to avoid injuries and damage.

9.1 Best Practices for Long-Term Chainsaw Maintenance

Regularly sharpen the chain and check tension to prevent wear. Clean or replace air filters and spark plugs as needed. Use the correct fuel-oil mix and store the saw properly. Follow the manual’s maintenance schedule to ensure longevity. Always refer to the Poulan Chainsaw Repair Manual for specific guidance on upkeep and repairs.

9.2 Resources for Further Assistance and Support

For additional help, visit the official Poulan Pro website for downloadable manuals and guides. Contact Poulan customer support for specific inquiries. Online forums and repair communities also offer valuable insights. Refer to authorized dealers for genuine parts and expert advice. Ensure to rely on official Poulan resources for accurate and safe repair practices.