Gelatin capsules are widely used in pharmaceutical and nutraceutical industries, offering sizes from 000 to 5, each with specific uses. Selecting the correct size ensures optimal fill capacity and efficiency, balancing formulation density and mass for precise dosing. Understanding capsule sizing is crucial for product integrity and consumer satisfaction.

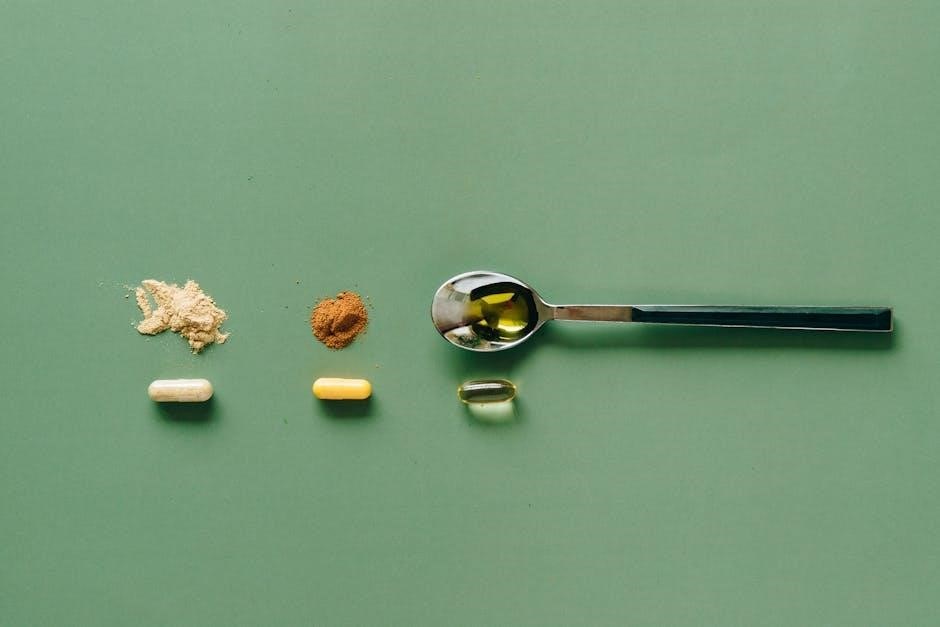

Overview of Gelatin Capsules and Their Uses

Gelatin capsules are widely used in the pharmaceutical and nutraceutical industries for enclosing active ingredients. Made from animal collagen or plant-based alternatives like HPMC or pullulan, these capsules are biodegradable and easy to digest. Their primary function is to protect the enclosed formulation from environmental factors and ensure controlled release. Gelatin capsules are versatile, catering to both dry and liquid ingredients, and are commonly used for vitamins, supplements, and medications. They enhance bioavailability, mask unpleasant tastes, and provide a clean, professional appearance. With their compatibility with various filling machines, gelatin capsules are a popular choice for custom formulations, offering a convenient and reliable way to deliver active ingredients.

Standard Gelatin Capsule Sizes

Standard gelatin capsule sizes range from 000 to 5, with 000 being the largest. Extended sizes like 00E and 0E offer additional options for specific needs.

Understanding Numerical Designations: 000, 00, 0, 1, 2, 3, 4, and 5

The numerical designations for gelatin capsules range from 000 (largest) to 5 (smallest). Each size corresponds to specific dimensions and capacities, ensuring uniformity across manufacturers. The numbering system is standardized, with higher numbers indicating smaller capsule sizes. This system applies consistently to gelatin, HPMC, and Pullulan capsules, simplifying selection for users. The designations are based on the capsule’s outer diameter and fill capacity, with size 000 offering the highest volume and weight capacity. Understanding these numerical designations is essential for compatibility with filling machinery and ensuring precise dosing. This standardized system aids in maintaining consistency and efficiency in pharmaceutical and nutraceutical production.

The Largest Capsule Size: 000

Size 000 is the largest standard gelatin capsule, offering the highest fill capacity. It measures approximately 25.70 mm in closed length and has an outer diameter of 8.53 mm. This size is ideal for formulations requiring a large volume, typically used for dense or bulky ingredients. With an approximate volume of 1.37 ml, it can hold up to 1,000 mg of material, depending on powder density. The 000 size is widely used in pharmaceutical and nutraceutical industries for high-dose applications. Its larger dimensions make it suitable for manual filling or high-capacity machinery, ensuring efficient production and precise dosing. This size is a popular choice for products requiring maximum fill capacity.

Extended Sizes: 00E and 0E

Extended sizes 00E and 0E are specialized gelatin capsule sizes designed for formulations requiring additional fill capacity. These sizes maintain the same outer diameter as their standard counterparts (00 and 0) but feature an elongated height, allowing for more material to be encapsulated. The 00E measures approximately 23.4 mm in height, while the 0E measures around 21.7 mm. These extended sizes are ideal for dense or bulky ingredients that exceed the capacity of standard 00 or 0 capsules. They provide flexibility without transitioning to a larger diameter, ensuring compatibility with most capsule-filling machinery. Extended sizes are particularly useful in scenarios where a higher volume of material needs to be encapsulated efficiently.

How to Choose the Right Capsule Size

Selecting the right gelatin capsule size involves considering formulation density, mass, and machinery compatibility. Accurate measurements ensure optimal fill capacity and product integrity, streamlining production processes effectively.

Factors to Consider: Formulation Density and Mass

When selecting a gelatin capsule size, formulation density and mass are critical. Density determines how tightly the powder packs, affecting fill volume, while mass influences the total weight of the active ingredient. Higher density formulations require larger capsule sizes to accommodate the same mass, ensuring the powder fits without overflow. Conversely, lower density materials may need smaller sizes to prevent excessive space. Understanding these factors ensures the capsule is neither underfilled nor overfilled, maintaining product consistency and efficacy. Proper measurement of these elements is essential for accurate size selection and efficient manufacturing. Using a capsule size chart can simplify these calculations.

Using a Capsule Size Chart for Accurate Selection

A capsule size chart is an essential tool for selecting the right gelatin capsule size. It provides detailed specifications, including volume, weight capacity, and dimensions for each size. By referencing the chart, users can match their formulation’s density and mass to the appropriate capsule size, ensuring optimal fill capacity; The chart also highlights differences between standard and extended sizes, such as 00E and 0E, which offer additional space for specific formulations. Using a capsule size chart simplifies the selection process, reduces errors, and ensures compatibility with filling machinery. It is a user-friendly resource that saves time and guarantees accurate results for various applications.

Capsule Size Chart and Specifications

A capsule size chart provides detailed specifications, including volume, weight capacity, outer diameter, and height. It helps users select the correct size for their formulation needs, ensuring accuracy and efficiency in capsule filling;

Volume and Weight Capacity by Size

Gelatin capsule sizes range from 000 to 5, each offering distinct volume and weight capacities. Size 000 has the largest volume at 1.37 ml and can hold up to 1,370 mg, making it ideal for dense formulations. Size 00 holds 0.95 ml, accommodating 950 mg, while size 0 holds 0.68 ml with a capacity of 680 mg. Sizes 1 through 5 decrease incrementally, with size 5 holding the least volume at 0.50 ml and 500 mg. These specifications guide users in selecting the optimal size for their specific needs, ensuring precise dosing and formulation efficiency.

Outer Diameter and Height Measurements

Gelatin capsule sizes vary in outer diameter and height, with size 000 being the largest. The outer diameter for size 000 is approximately 9.91 mm, with a height of 25.7 mm. Size 00 measures 8.53 mm in diameter and 23.4 mm in height, while size 0 has a diameter of 7.65 mm and a height of 21.7 mm. Sizes 1 through 5 decrease progressively, with size 5 having the smallest dimensions at 5.35 mm in diameter and 14.3 mm in height. These precise measurements ensure compatibility with capsule-filling machinery and help in selecting the appropriate size for specific formulations and applications.

Actual Volume and Fill Capacity

Gelatin capsule sizes are defined by their actual volume and fill capacity, which are critical for determining the appropriate size for a given formulation. The largest size, 000, has an actual volume of approximately 1.37 ml and can hold up to 1,370 mg of material. Size 00 offers 0.95 ml volume and 950 mg capacity, while size 0 holds 0.68 ml and 680 mg. Sizes 1 through 5 decrease progressively, with size 5 having a volume of 0.50 ml and a capacity of 500 mg. These measurements ensure precise dosing and compatibility with various filling machinery, making it essential to match the capsule size to the formulation density and mass for optimal results.

Capsule Filling Considerations

Capsule filling requires compatibility with machinery, considering powder density for accurate measurements. Proper calculation ensures the right quantity, optimizing production efficiency and product quality.

Compatibility with Filling Machinery

Standard gelatin capsule sizes (000 to 5) are designed to work seamlessly with most capsule filling machines. Ensuring compatibility is crucial for efficient production, as improper sizing can lead to jams or inconsistent filling. Extended sizes like 00E and 0E are also compatible with standard machinery, offering flexibility for specific formulations. Always verify the machine’s specifications to match the capsule size, ensuring smooth operation and optimal results. Using the correct size prevents waste and guarantees precise dosing, making it essential to align capsule and machine capabilities for successful production runs.

Calculating the Right Quantity for Your Needs

To determine the correct number of capsules, consider the total weight of your formulation and the desired dose per capsule. Using the capsule size chart, match the volume and weight capacity to your needs. For instance, size 000 holds up to 1,370 mg, while size 5 holds approximately 150 mg. Calculate the total number of capsules by dividing the total formulation weight by the dose per capsule. Always account for waste and overage to ensure sufficient supply. This step ensures efficient production and precise dosing, avoiding shortages or excess material.

Common Uses for Each Capsule Size

Gelatin capsule sizes cater to diverse applications, from pharmaceuticals to nutraceuticals. Size 000 is ideal for bulky powders, while smaller sizes like 5 are suited for precise, low-dose formulations.

Typical Applications of Size 000 to 5

Gelatin capsule sizes range from 000 to 5, each tailored for specific uses. Size 000, the largest, is often used for bulky or dense powders, while size 00 is ideal for common supplements. Size 0 and 1 are popular for standard dosages, with size 1 being a favorite for vitamins. Sizes 2, 3, 4, and 5 are smaller, typically used for low-dose active ingredients or precise formulations. This range ensures versatility, accommodating various product needs and preferences, making gelatin capsules a flexible choice across industries.

Manufacturing and Quality Assurance

Manufacturing involves precise production processes, ensuring each capsule meets strict quality standards. Rigorous testing guarantees consistent size, strength, and material purity, maintaining reliability across all batches.

Ensuring Proper Fit and Seal

Proper fit and seal are critical in gelatin capsule manufacturing to prevent leakage and ensure product integrity. Capsules undergo rigorous testing to verify locked length, material integrity, and closure strength. Advanced machinery ensures precise alignment of the cap and body, while quality control measures validate every batch. The manufacturing process includes checks for diameter consistency, surface smoothness, and moisture content to guarantee a reliable seal. These steps ensure capsules maintain their structural integrity, protecting the enclosed formulation and preserving potency. Proper fit and seal are essential for consumer safety, product efficacy, and compliance with regulatory standards.

Selecting the right gelatin capsule size is vital for optimal formulation performance. Consider density, mass, and machinery compatibility, using size charts for accurate selection. Proper fit ensures product integrity.

Final Tips for Selecting the Optimal Gelatin Capsule Size

When choosing the right capsule size, consider your formulation’s density and mass to ensure accurate fill capacity. Refer to a capsule size chart for precise measurements. Higher numbers indicate smaller sizes, with 000 being the largest. For extended fill needs, 00E and 0E are ideal. Compatibility with filling machinery is crucial, so verify your equipment’s specifications. Calculate the quantity needed based on density and desired fill weight. Using the correct size ensures proper fit and seal, maintaining product integrity and consumer satisfaction. Always consult a comprehensive guide or interactive chart for optimal selection.